PRODUCT SOLUTION

Rudder

The rudder plays a vital role in vessel maneuvering. Depending on the ship's purpose and route, the balance between course-keeping and turning performance differs. Nakashima Propeller offers an ideal lineup of rudders optimized to achieve the best balance between these two requirements.

Nakashima Propeller has a technical partnership with Becker Marine Systems (BMS) of Germany and manufactures and sells various types of rudders, including the flap rudder.

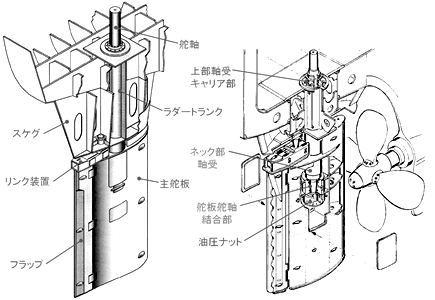

A key feature of Nakashima’s rudders lies in the structure of the rudder trunk.

By integrating the carrier section, sealing section, and neck bearing into a unified rudder trunk structure, a significantly simpler design is achieved compared to conventional rudders, reducing installation man-hours. The carrier section employs self-aligning roller bearings, which help reduce uneven wear of the neck bearing.

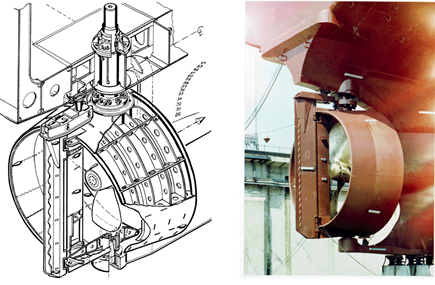

Flap Rudder

The flap rudder, a flagship product of Nakashima Propeller and synonymous with the Becker rudder, supports a wide range of vessel types, from small to large. With over 2,800 units sold, it is widely trusted across the industry.

The flap effect allows the rudder to generate more than double the lift of a conventional rudder of the same area, significantly improving maneuverability.

A linkage mechanism is provided so that when the main rudder plate is turned 45 degrees, the flap turns 90 degrees relative to the ship's longitudinal axis. Specifications supporting a rudder angle of up to 60 degrees are also available.

For medium to large-sized semi-hanging rudders, Nakashima adopts the KSR-type rudder trunk structure.

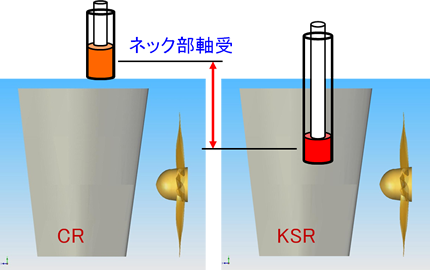

KSR-Type Rudder Trunk Structure Rudder

A rudder designed to compete with the mariner rudders widely used in medium and large vessels.

By positioning the neck bearing of the rudder trunk near the center of rudder pressure inside the rudder blade, the bending moment on the rudder stock is reduced, allowing for thinner rudder stock diameters and blade thickness.

Since there is no rudder horn, no machining is needed for shaft alignment, significantly reducing the overall installation man-hours of the rudder system and also greatly reducing weight (by more than 30%).

Compared to rudders with rudder horn structures, the effective rudder area increases, and since the entire rudder becomes a movable part, steering performance is also improved.

This rudder trunk structure is applied to medium and large semi-hanging rudders (conventional rudder, flap rudder, twist rudder).

Conventional Rudder (CR)

A very simple rudder structure that shares the same rudder trunk as general flap rudders.

In the case of medium and larger semi-hanging rudders, a hub section is provided at the upper end of the rudder blade, where it is taper-coupled with the rudder stock and fixed with a hydraulic nut.

If the design conditions such as ship speed are severe, a structure in which the rudder trunk is housed inside the rudder blade (KSR-type) is adopted.

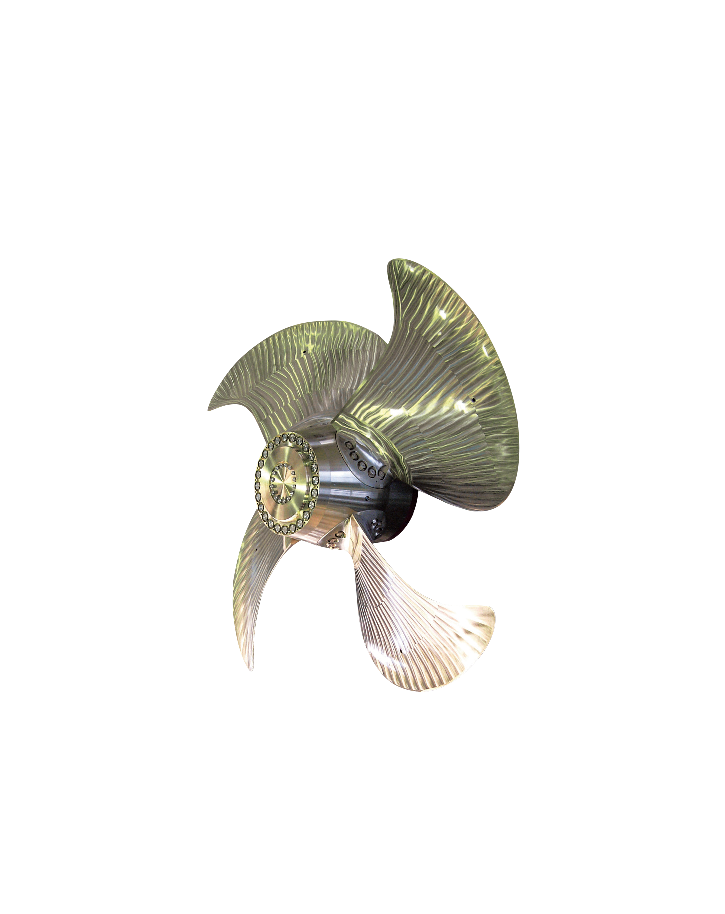

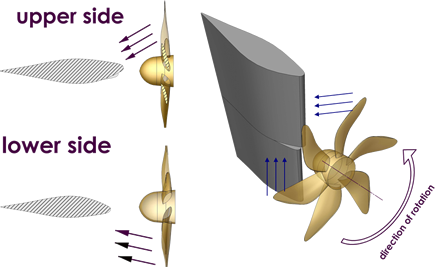

Twist Rudder

A rudder adopting the KSR-type trunk structure, with the rudder leading edge twisted to the left and right above and below the extension of the propeller shaft centerline, and employing an optimal cross-sectional shape.

It offers significant advantages as an energy-saving rudder for large high-speed vessels, with an expected efficiency increase of approximately 2%. Further efficiency improvements are possible through combinations with other energy-saving mechanisms, such as with a bulb or flap.

In Korea, it is recognized as the standard rudder for large high-speed container ships, and in Japan, it was first ordered by Mitsubishi Heavy Industries Nagasaki Shipyard in 2008 for four large RoRo vessels. This product is imported and sold from BMS.

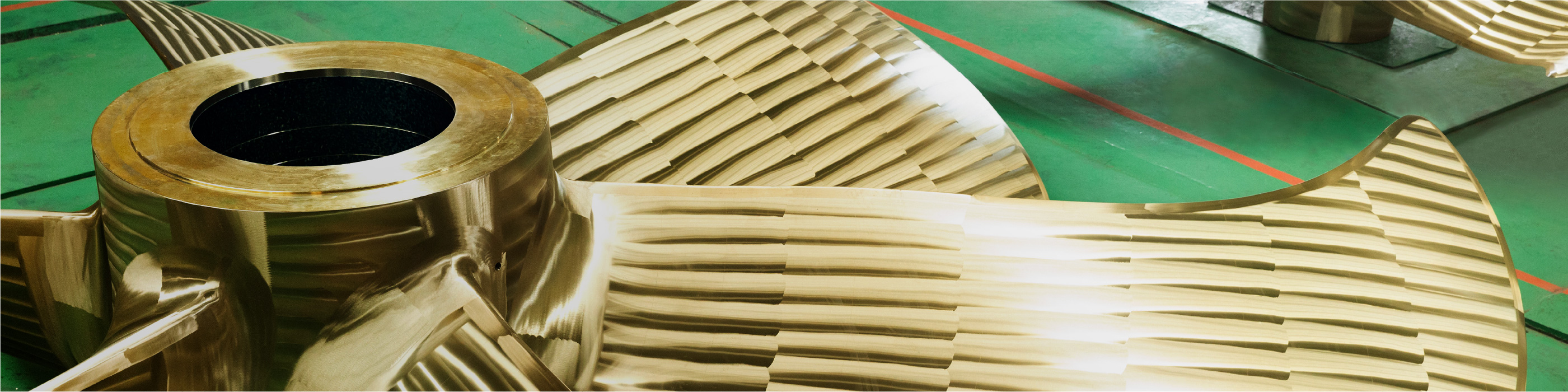

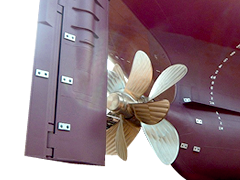

Kort Nozzles and Nozzle Rudders

Other then the above-mentioned products, Nakashima Propeller also manufactures and sells fixed Kort nozzles and nozzle rudders (with fixed fins and with flaps).

Advantages:

- Increased bollard pull

- Improved propulsion efficiency

- Enhanced maneuverability

- Reduced vibration

- Protection against propeller damage

- Energy-saving effects

Suitable for the following vessels:

- Tugboats

- Fishing vessels

- Survey ships

- Supply and special-purpose vessels

- Dredgers and cable-laying vessels

etc.