AFTER SUPPORT &

MAINTENANCE

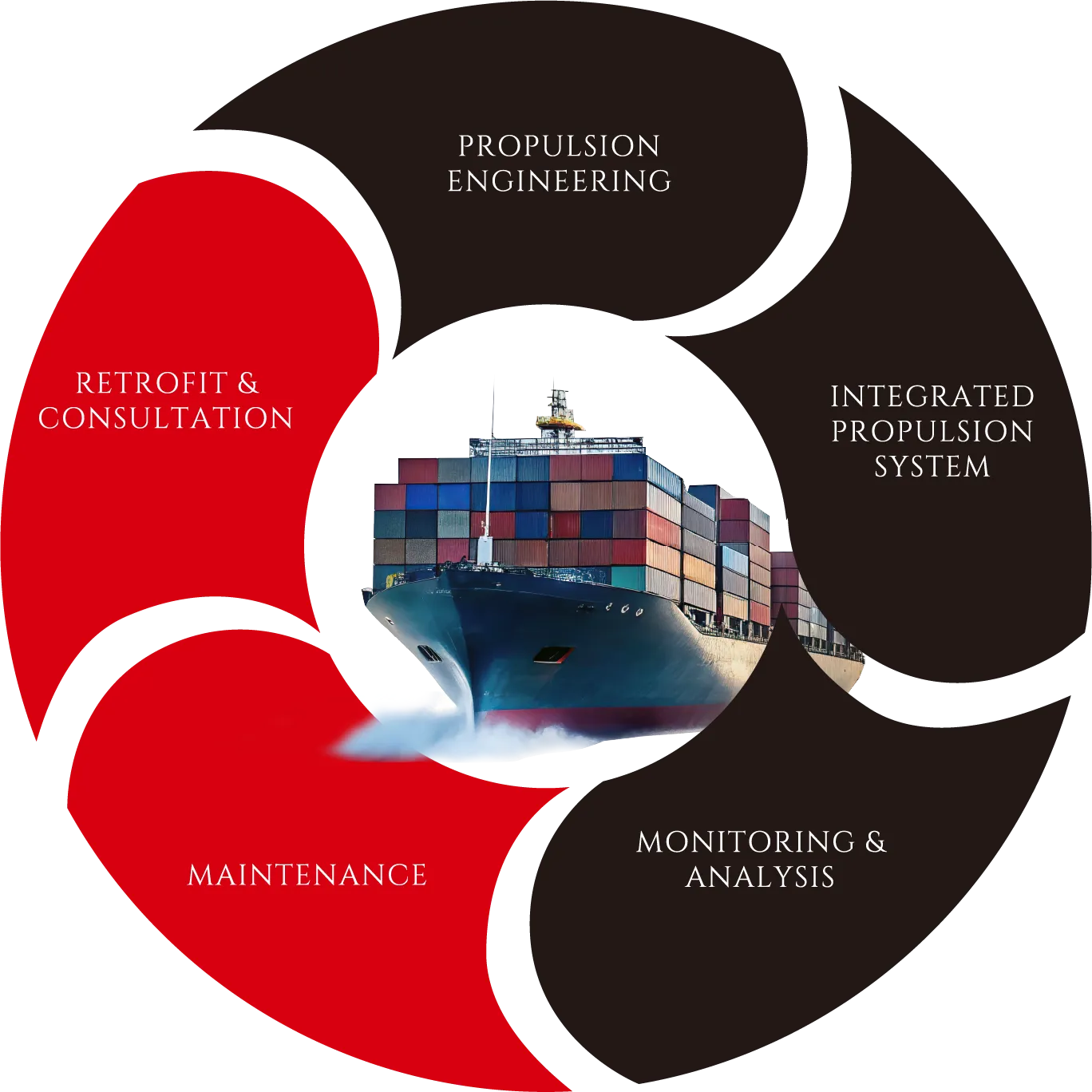

One-Stop System from Design to After-Support

To deliver peace of mind to customers around the world, Nakashima

Propeller has established a global service and support network.

Retrofit & Fuel Efficiency Improvement Solutions

We offer retrofit services by replacing propellers with optimized models based on actual vessel operation. We also support recycling of scrapped propellers and provide consulting to improve propulsion performance for better fuel efficiency on vessels in service.

Propeller Repair and Maintenance Services

We offer repair of damaged propellers, edge cutting to restore efficiency lost due to aging, and polishing/cleaning services.

Integrated Design for Optimal Propulsion Performance

Using a large-scale CFD system, we design optimal propellers that satisfy requirements for efficiency, cavitation, and strength. The stern area is holistically designed with the propeller as the core.

Package Solutions of Propulsion Equipment and Energy-Saving Devices

We provide packaged solutions combining propellers with energy-saving devices to improve overall propulsion performance.

Monitoring and Analysis of Propeller Operation

We monitor propeller condition after delivery and provide visibility into fuel efficiency. Solutions are proposed in response to aging and wear.

AFTER SUPPORT

A Wide Range of Support Based on Proven Results and Experience

Nakashima delivers satisfaction and peace of mind with a comprehensive menu of support services:

- Repair work in case of damage / correction of bends, build-up welding of cavitation areas and damaged parts, splicing and welding repairs, etc.

- Dispatch of technicians for regular inspections

- Advice on maintenance and inspections

- Prompt response at the time of parts replacement

Please contact our After-Sales Service Department or the nearest sales office.

Worldwide Support System

To provide reliable support to customers around the world, we have established a worldwide service and support system. When making an inquiry, please provide information about the damage situation and recent operation records.

MAINTENANCE

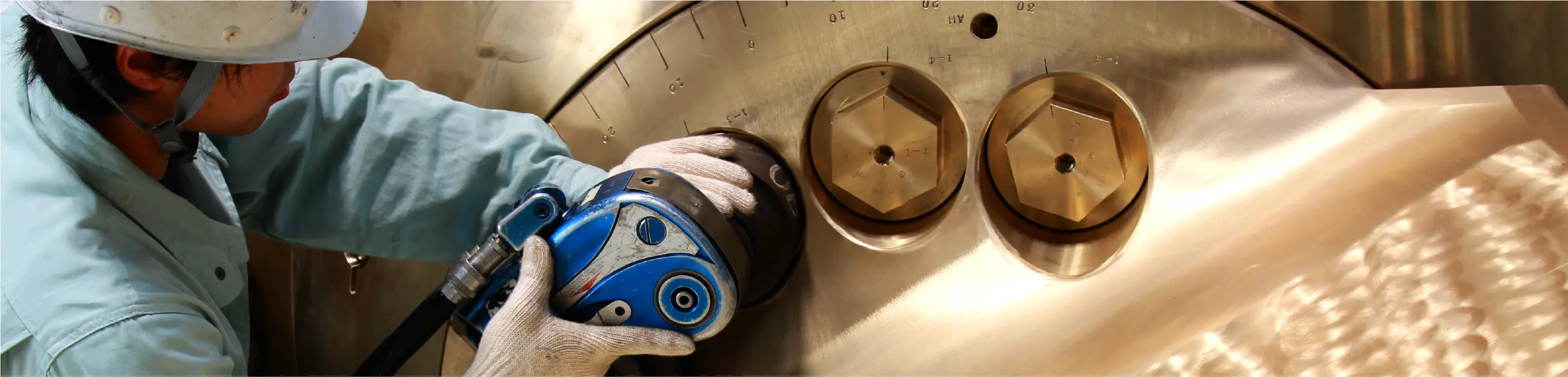

Reliable Maintenance by Skilled Technicians

Nakashima Propeller handles everything from the design to the manufacturing of all types of marine propulsion systems, and as a manufacturer, we have extensive experience and a proven track record. Even during regular inspections or repair work, our expert technicians—well-versed in the details of each product—provide support to ensure safe and comfortable voyages for our customers. Each repair facility is equipped with dynamic balancing machines, enabling the repair of high-RPM propellers for high-speed vessels. We also dispatch specialized technicians for the repair and maintenance of controllable pitch propellers and thrusters, allowing for rapid response in emergencies.

PROPOSAL

Recommendations from a Propulsion

Equipment Manufacturer

[Edge Cutting for Improved Operational Performance]

"Has your engine been running torque-rich since the ship was built?"

"Are you considering installing energy-saving devices?"

For shipowners with such concerns, edge cutting of the propeller can lead to further improvements in operating conditions. Please feel free to consult with us.

[Regular Thruster Maintenance]

Some components of thrusters, such as sealing systems and O-rings, use rubber materials, which generally have a service life of 6 to 8 years. Bearings used in rotating parts also have limited lifespans. If the thruster becomes inoperable due to poor maintenance, additional costs such as tugboat fees and labor expenses may arise. We urge you to recognize the importance of regular inspections and maintenance to ensure continued safe operation in the future.