MANUFACTURING

MANUFACTURING

One of the World’s Leading

Propeller Factories

“The Fusion of Craftsmanship and Digital Technology”

To reproduce the complex three-dimensional shapes unique to fluid dynamic products such as propellers from two-dimensional design data, we integrate skilled craftsmanship with proprietary “digital technologies” across all stages of the manufacturing process—casting, machining, and finishing—creating propellers that make full use of these capabilities.

Advanced Technology: Digital Technology

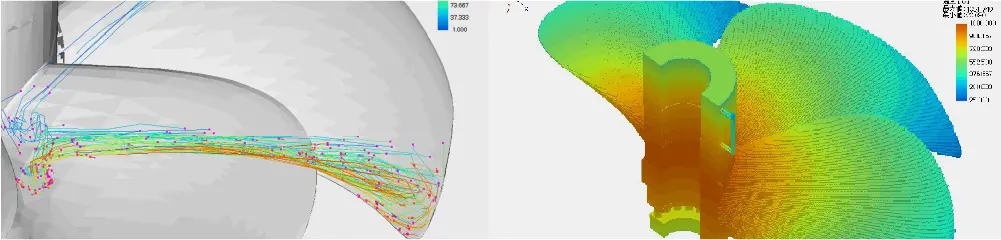

The key to fluid products like propellers is the faithful reproduction of the designed geometry. Based on many years of experience in propeller manufacturing, we collaborate with equipment manufacturers to jointly develop and implement high-precision and efficient production facilities. Our continuous efforts aim to establish even more optimal manufacturing techniques.

Craftsmanship: Human Skill

Craftsmanship is essential for one-off production and is particularly vital in forming the delicate curved surfaces of propeller blades—something that cannot be replicated by even the most advanced machining. While cast products are generally formed by first creating a pattern model and then a mold, our custom-built propellers—each designed to the optimal shape—are molded without using a pattern model. Instead, we use a unique mold fabrication method called the “mawashi-gata” (rotating mold) technique. The mold’s master shape is created, then positioned using NC data that defines displacement (angle and height) from reference points. Skilled workers manually interpolate between these points with sand to form an accurate mold surface. From the very first step of mold production, we are already pursuing an individually optimized shape. Moreover, craftsmanship also plays a vital role in the finishing process. Surface polishing that detects and smooths out deviations as small as 1/100 mm on the blade surface, and fitting work with the shaft, all rely on high-level skills and human sensitivity.

Note: The “1/100 mm deviation” mentioned here refers not to an absolute error from the design value but to a relative error that stands out within continuous curved surfaces.