ANALYSIS AND DESIGN TECHNOLOGY

ANALYSIS AND DESIGN TECHNOLOGY

Analysis & Design Technology

– R&D for Creating High-

Performance Propellers

R&D for Creating High-Performance Propellers

To design optimal propellers, it is essential to predict their performance and verify the accuracy of those predictions. At Nakashima, we conduct performance predictions using CFD (Computational Fluid Dynamics) simulations and validate the results through model testing. A high-performance propeller must meet three key performance criteria: efficiency, cavitation, and strength. A propeller that successfully balances all three is truly the optimal solution for a given vessel.

These performance aspects are often in conflict. For example, a propeller designed solely for maximum efficiency may result in thinner blades, leading to insufficient strength. Excessive cavitation may also occur, causing vibration that can damage the hull or rudder. Thus, it is critically important to balance efficiency, strength, and cavitation performance through careful design and verification using simulation.

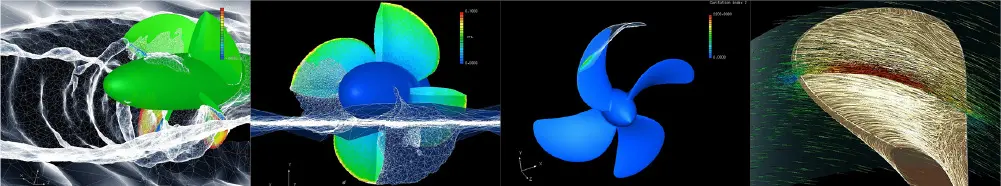

Unmatched Core Processing Power: Performance Prediction Through CFD Simulation.

At Nakashima, we utilize CFD with an overwhelming number of cores to visualize and analyze fluid flow. With the introduction of large-scale CFD, it is now possible to simulate more complex and detailed phenomena in a shorter amount of time. This enables us to estimate propeller performance, simulate cavitation, and calculate erosion risk.

Applying R&D to New Design Development

At Nakashima, we reflect our years of accumulated experience in CFD simulations and model testing, which form the backbone of propeller design. By continuously feeding the results of these simulations and experiments back into our standard design processes, we have enhanced design accuracy.

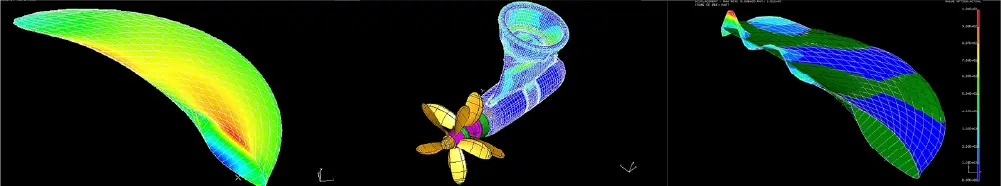

Structural Integrity Evaluation: FEM

In order to ensure the blade strength of propellers used in complex flow conditions and to secure the structural performance of products, a structural evaluation process during the initial design phase is essential. For this, we effectively apply structural analysis technologies to evaluate the soundness of our products.

By advancing this R&D, we do not limit ourselves to conventional designs. Instead, we actively develop new propeller shapes in-house, such as NHV and tip rake types.

NHV Type

Conventional Type