PRODUCT SOLUTION

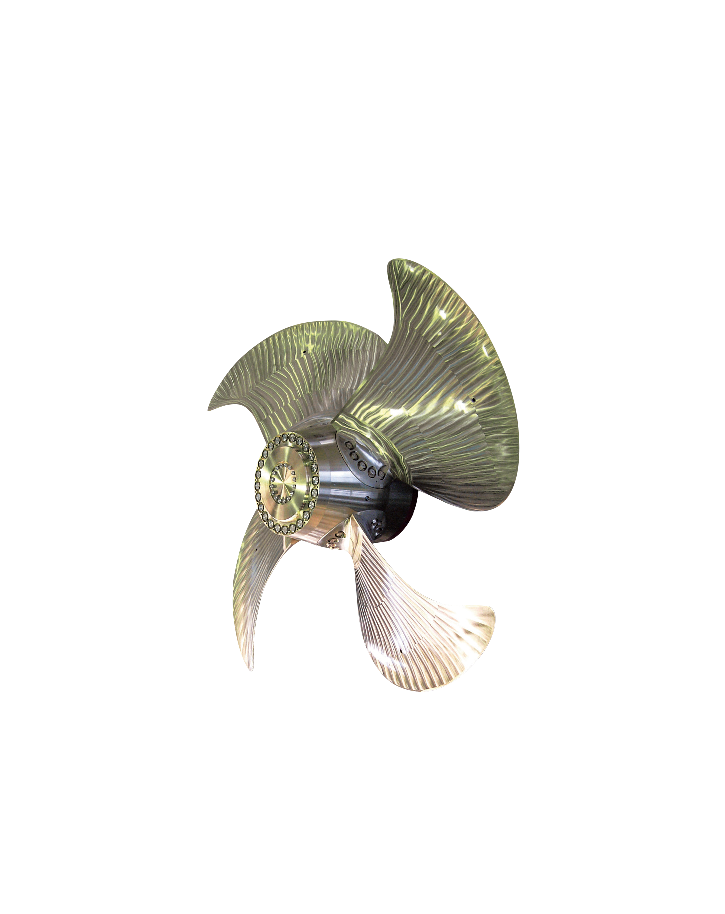

Controllable Pitch Propeller (CPP)

What Is a Controllable Pitch Propeller?

A controllable pitch propeller allows for fine adjustment of the blade angle, making it easy to switch between forward, stop, and reverse thrust. When combined with a side thruster, it enables smooth maneuvering during port entry, departure, and berthing operations that require frequent changes in speed and direction. It also provides immediate response from full ahead to full astern in emergency stop situations.

By adjusting the blade pitch, the engine can operate continuously at its most efficient load, while vessel speed is freely controlled contributing to reduced fuel consumption and lower NOx emissions. Thanks to these advantages, CPPs are widely adopted in various vessel types, including fishing vessels, tankers, ferries, and tugboats.

Leveraging our proprietary design methods developed from fixed pitch propeller expertise, we determine the optimal pitch and camber distribution to achieve high-efficiency performance. The blade cross-section is designed to provide a flatter pressure distribution across the surface, resulting in improved cavitation performance as well.

Key Features

-

Enables optimal operation that makes full use of engine output while minimizing fuel consumption.

-

Continuous control of blade pitch from full ahead to full astern allows for efficient operation, high stopping performance, and reduced berthing time.

-

Operates at the optimal efficiency point by comprehensively considering propulsive efficiency and engine fuel consumption, resulting in further fuel savings.

-

Capable of achieving the required vessel speed or thrust even under widely varying load conditions ideal for trawlers, tugboats, and other vessels with fluctuating demands.

- Reducing the propeller pitch angle during rough sea conditions helps prevent engine torque overload (torque-rich conditions), ensuring smoother and safer operation compared to normal cruising pitch settings.

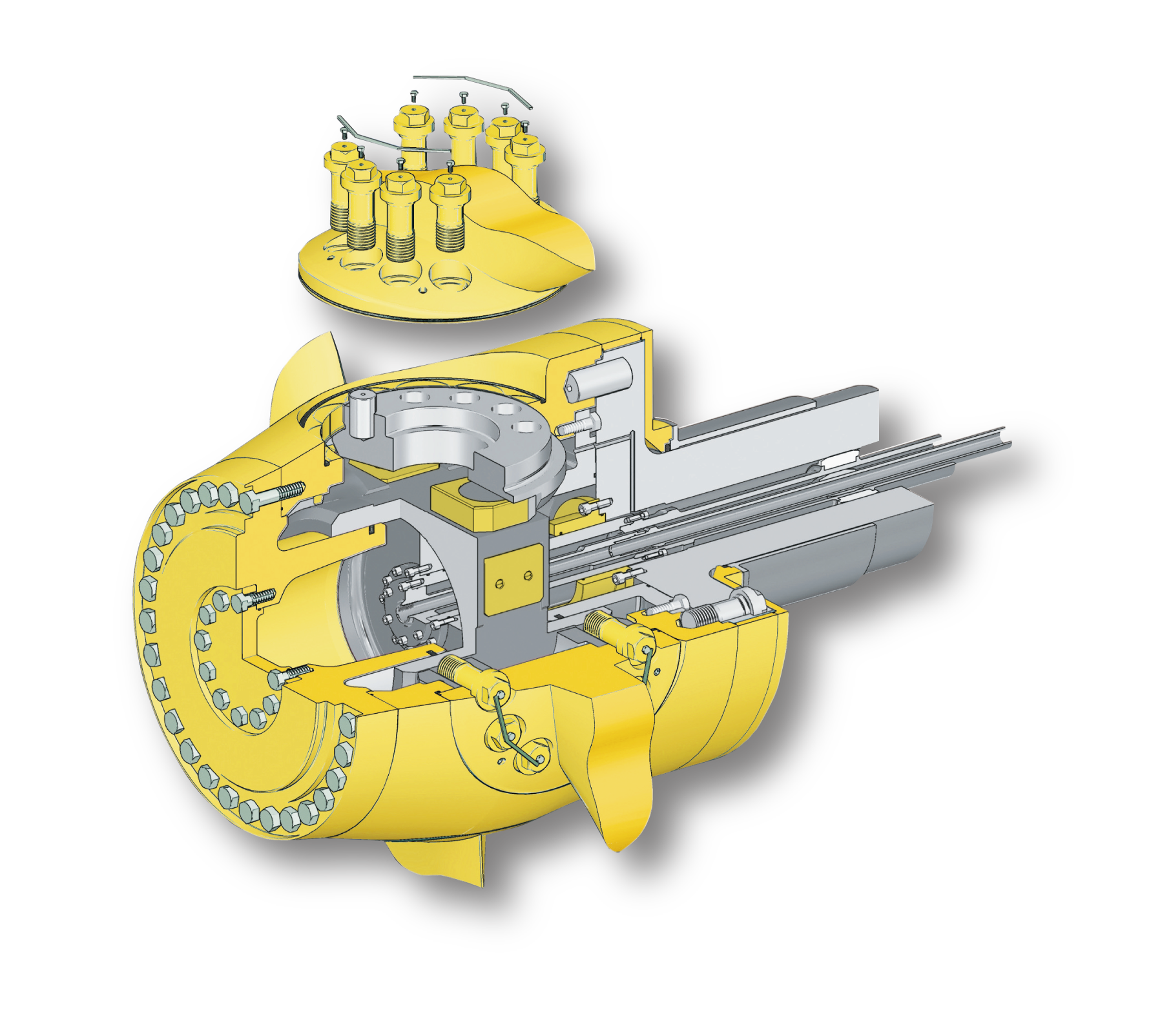

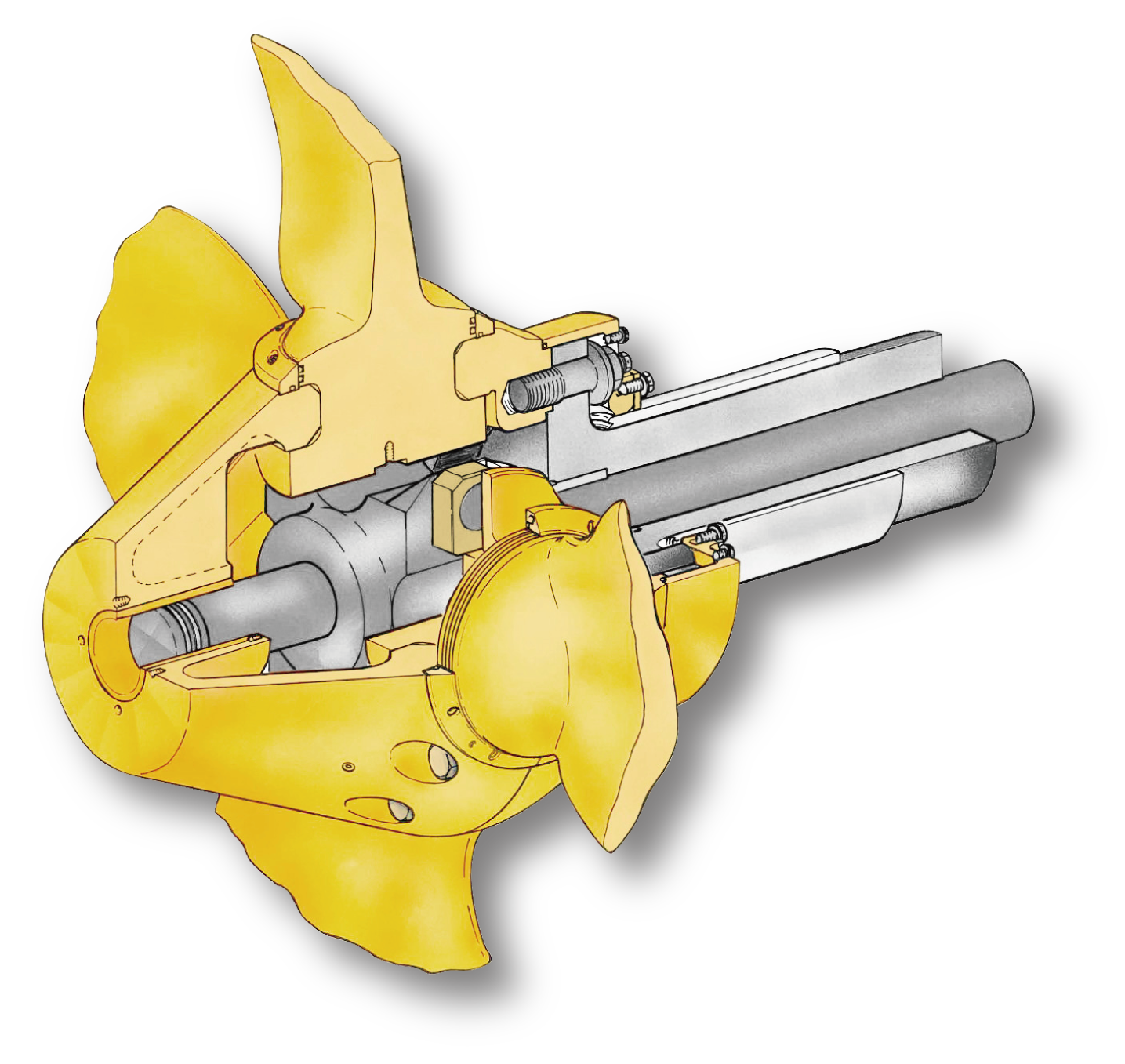

MODEL XL For Large Vessels

This model is primarily used for large vessels. It features a hydraulic cylinder located inside the outboard propeller hub, which directly actuates the blades to adjust the pitch angle.

Because the pitch actuation force is not transmitted through the oil supply pipes, there is no risk of pipe deformation. Compared to rod-type mechanisms, this design provides superior pitch control accuracy.

Furthermore, the use of proportional control valves allows for smooth and precise adjustments, even for fine pitch corrections such as ALC (Automatic Load Control).

The system includes a dual hydraulic circuit with both normal and emergency control valves, as well as separate pumps for main and auxiliary pitch control oil enhancing overall safety and reliability.

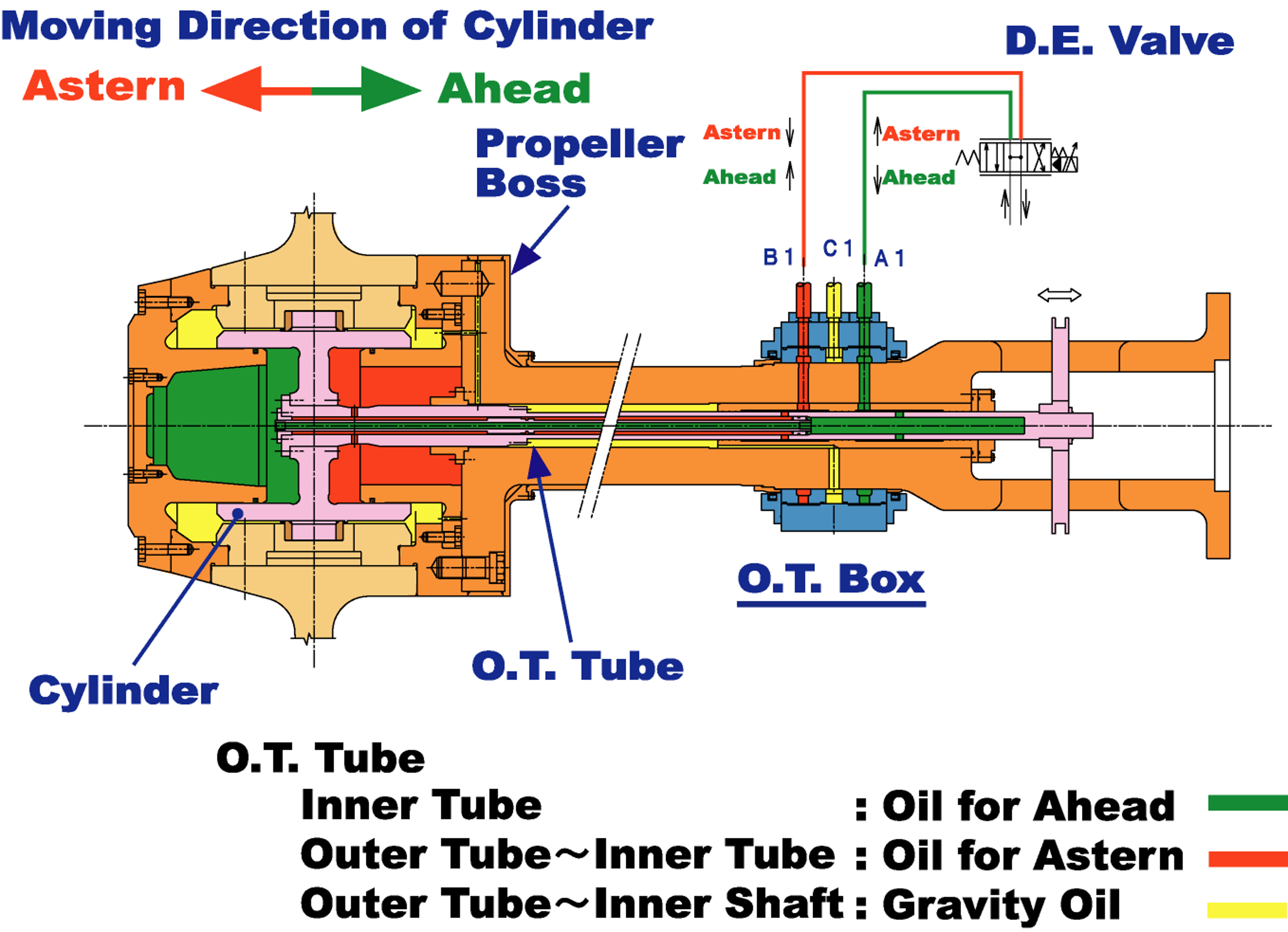

[Hydraulic Circuit Diagram]

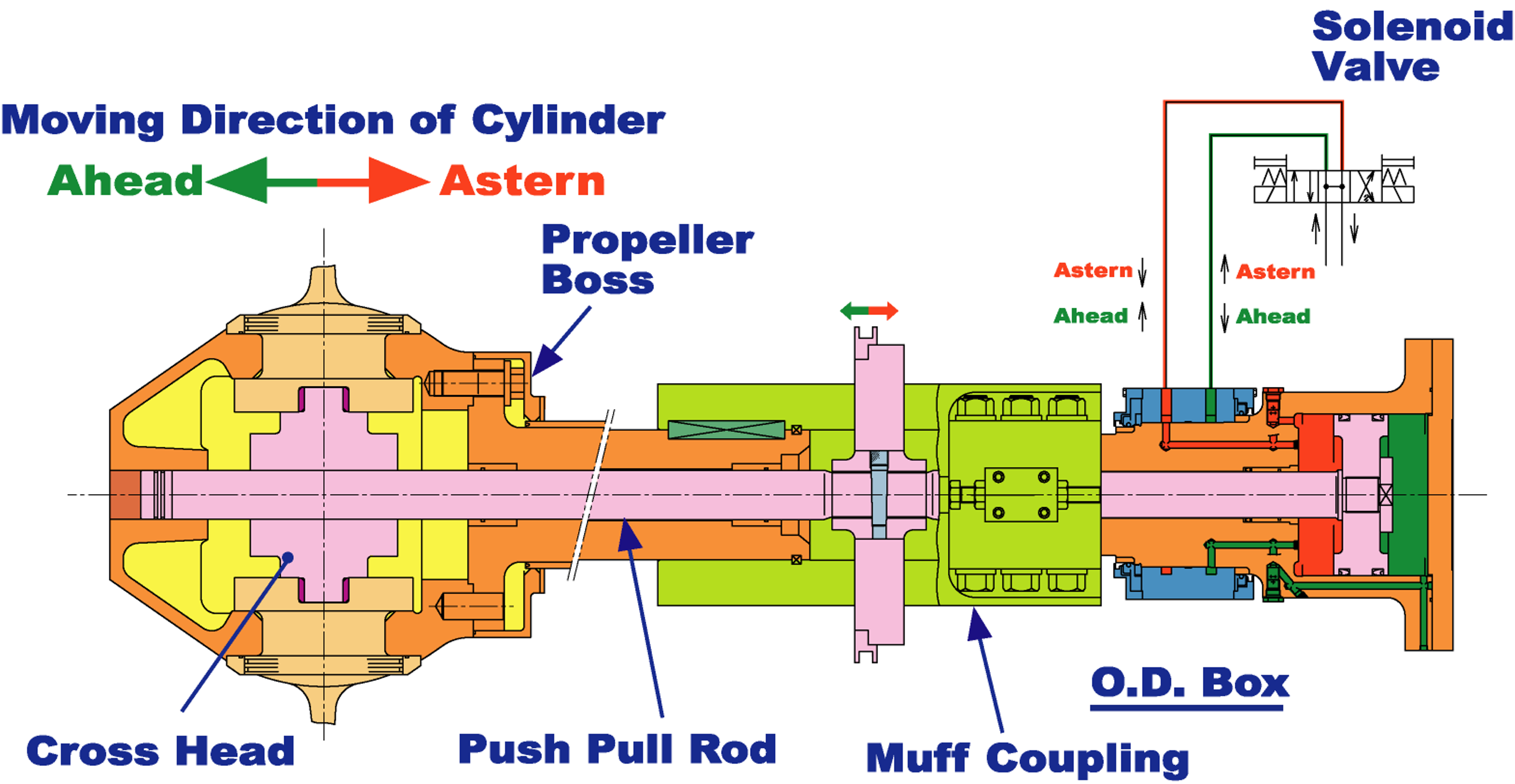

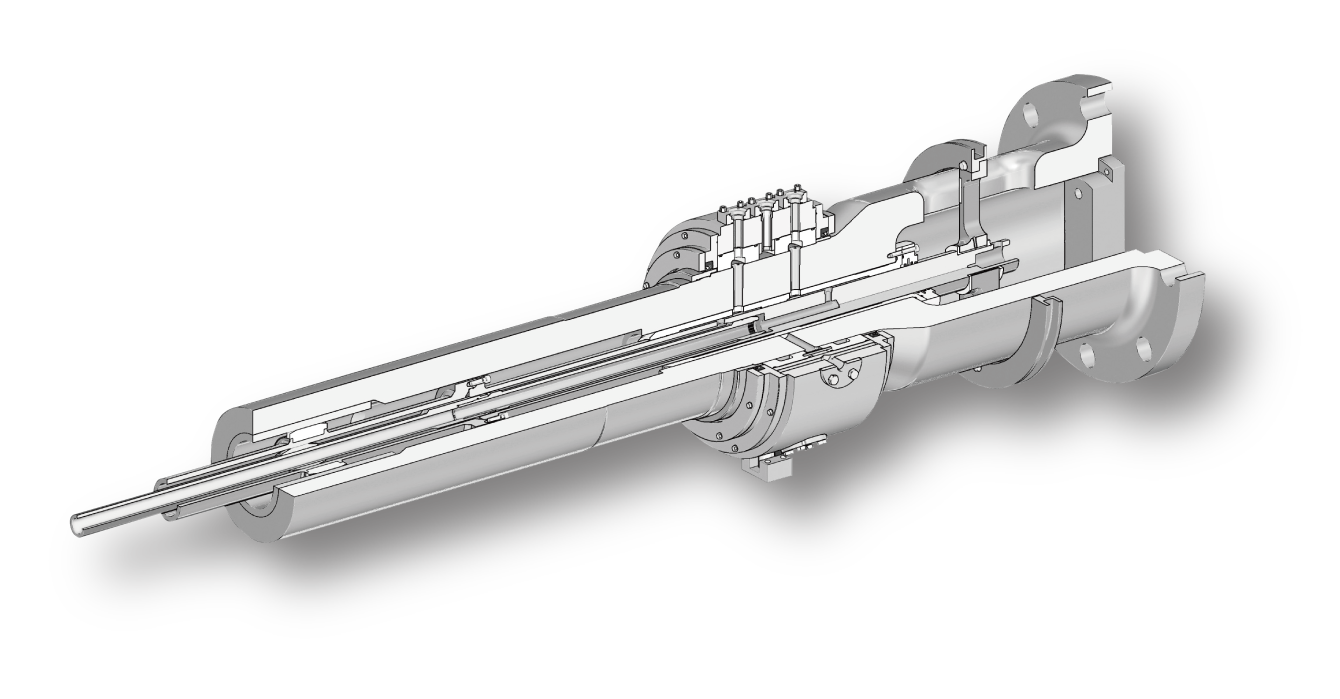

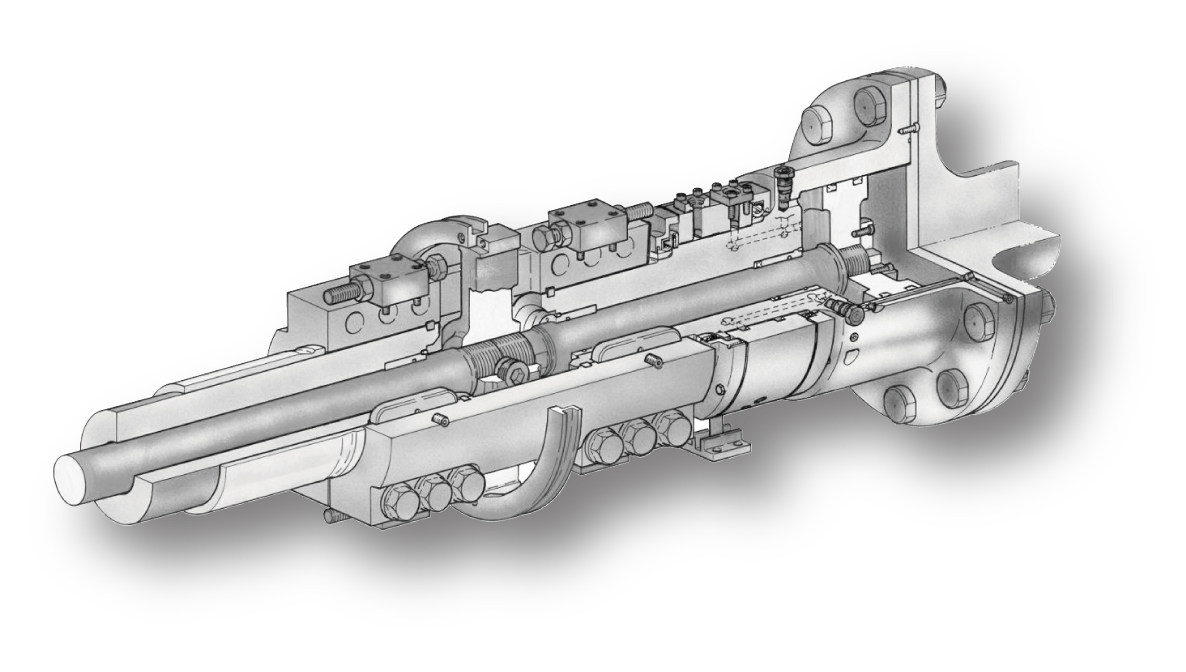

MODEL XS For Medium and Small Vessels

This model is primarily used on medium and small sized vessels. The hydraulic cylinder that controls the blade pitch is located inside the intermediate shaft on the inboard side. Hydraulic oil from the pump in the hydraulic unit flows through a solenoid valve and enters the OD box at the centre of the cylinder shaft.

When the pitch control handle is operated, a signal is sent, causing pressurized oil to flow from the OD box through a pilot check valve and into the cylinder. The resulting piston motion is transmitted via the pitch rod to the crosshead, which adjusts the blade angle accordingly. From its simple construction, this system helps reduce maintenance costs. The interior of the hub is lubricated with grease instead of oil, eliminating the risk of oil leakage from the hub and thereby reducing environmental impact.

[Hydraulic Circuit Diagram]